Takashima Sangyo (Shenzhen) Ltd.

-

86-755-29619088

-

852-23771473

About Takashima

Contribute to Society with Intelligent Manufacturing

- Company profile

-

Takashima Sangyo (Shenzhen) Ltd. is a wholly foreign-owned Japanese enterprise.

■ In April of 1995, Shenzhen Baoan Takashima Precision Products Factory (Enterprises of Three Import and Compensation Trade) was established.

■ In September of 2004, the business outside clock was seperated from Shenzhen Baoan Takashima Precision Products Factory, and Takashima Sangyo (Shenzhen) Ltd. (exclusively foreign-owned enterprise) was incorporated.

■ In September of 2013, Shenzhen Baoan Takashima Precision Products Factory, focusing on spare and accessory parts of clock, was closed down, and its business was incorporated into Takashima Sangyo (Shenzhen) Ltd.Takashima Sangyo (Shenzhen) Ltd.

Registered capital: 8000000 HKD

Address: Block E, Haixinguang Industry Zone, Zhenmei Road, Guangming, Shenzhen

Plant area: 7520㎡

Employee: 150

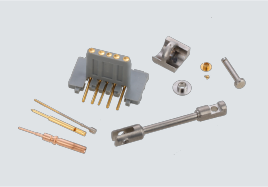

Main business scope: Precise hardware parts of clock including adjuster, pusher, and in-built parts, etc.; various relevant precision hardware accessories including connectors, optical communication, IT, medical treatment, new energy, and camera, etc.

- Management idea

-

-

1

Satisfy customer’s expectation

Contribute to society with intelligient manufacturing -

2

Care for the environment

Hand down from generation to generation -

3

Keep alive

Challenge and progress

-

- Partners

- Quality policy

- Exert team power, persist in Q.C.D. first,

Fully understand customer's expectation, deliver satisfaction and reassurance to the customer.

■ To embody high-efficiency team quality with a good quality system.

■ To continue to carry out〖 P.D.C.A 〗cycle.

■ To persist in three principles of site, real object, and reality, and solve the problem by principle means. The entire personnel challenge the goal of "improving quality".

- Basic environmental guideline

- ■ Observe the regulations related to national and local environmental laws as well as the customer's environmental criteria.

■ Improve the environmental awareness and capacity of the whole personnel, and proactivley participate in environmental-protection activity.

■ Carry out energy saving and reduction and pollution-prevention activity, reasonably use energy, and protect global environment.

■ Implement environmental management to continuously improve the environment.

■ Take control measures to ensure that the whole manufacturing process conforms to relevant material regulations of environmental management.